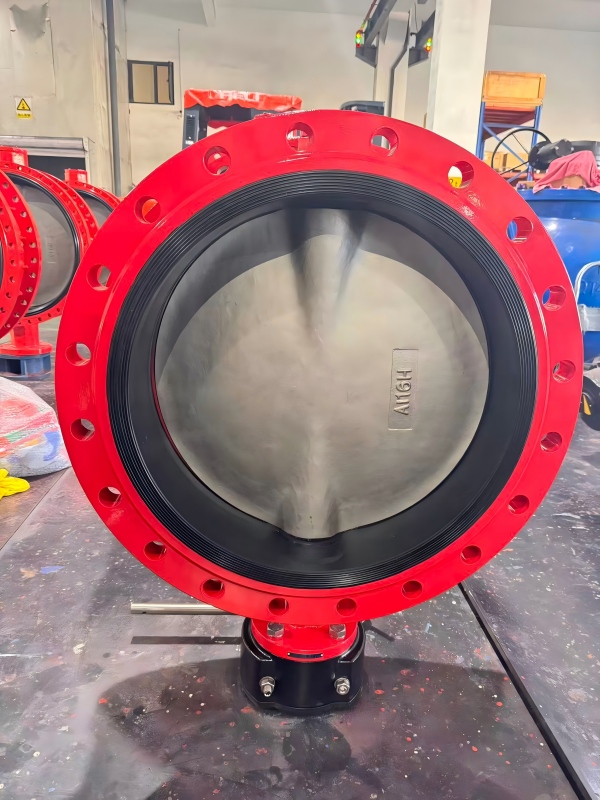

Nibii ni akɛwoɔ valve lɛ nɔ lɛ saa valve lɛ he nitsumɔ lɛ he tɛ̃ɛ, gbɛ ni atsɔɔ nɔ akɛwoɔ mli kɛ anɔkwayeli ni yɔɔ paipii gbɛjianɔtoo lɛ mli lɛ.TWSbaatsɔɔ tsakpaai wuji kɛ amɛsui lɛ amli kuku yɛ sane nɛɛ mli.

Jeŋ muu fɛɛ tsakpaa gbɛ lɛ haa anáa naatsii kɛtsɔ bolt ni akɛfiɔ flanges enyɔ lɛ nɔ.

Nɔ ni afɔɔ namɔ yɛ hiɛ henɔi:

-He ni jeɔ kpo: Nɔ ni afɔɔ feemɔ fe fɛɛ, ni nɔ ni akɛfiɔ he lɛ jeɔ kpo 2-3mm, ni sa kɛha nɔnyɛɛ babaoo (PN10-PN25).

-Concave-convex ŋwɛi: nitsumɔ ni hi jogbaŋŋ ni akɛwoɔ mli, ni sa kɛha la ni shãa kɛ nibii ni yɔɔ gbeyei.

-Groove hiɛ: nɔ ni hi fe fɛɛ ni akɛfiɔ he, ni akɛtsuɔ nii kɛhaa adafitswaa ni yɔɔ oshara waa kɛ shihilɛi ni mli wa waa.

-Ring tsakpaa ŋwɛi: Dade ring gasket, ni afee kɛha nɔnyɛɛ ni nɔ kwɔ kɛ hulutsoo ni nɔ kwɔ nitsumɔi. Sɛɛnamɔi ni yɔɔ he: Anyɛɔ akɛ he fɔ̃ɔ nɔ ni ajieɔ kɛjɛɔ mli lɛ mlɛo.

Sɛɛnamɔi: gbee ni da kɛ muji, jara ni wa.

Valve lɛ yɛ nɔ ko ni bɛ flange, ni akɛ bolts kakadaji ni yɔɔ paipii flange lɛ teŋ lɛ fiɔ he. Nɔ ni fata sui titrii ni yɔɔ mli lɛ ahe ji tsɔne ni yɔɔ kuku, tsumaa ni tsiimɔ waaa, kɛ shika ni akɛtsuɔ nii. Shi kɛlɛ, ebiɔ ni akɛwo mli jogbaŋŋ, ni ewa akɛ abaakwɛ nɔ jogbaŋŋ. Akɛ nɛkɛ ŋaa nɛɛ tsuɔ nii babaoo yɛ...ŋmeii valvɛikɛkwɛmɔ valvɛi lɛ.

Threaded connection ji tsɔne ni akɛtswaa nibii ni akɛ threaded fasteners tsuɔ nii kɛtsaa fãi ni abaanyɛ ajie kɛjɛ mli be fɛɛ be.

Sɛɛnamɔi ni yɔɔ tsɔne ni akɛwoɔ tsɔne mli lɛ he: Bɔ ni afeɔ lɛ babaoo lɛ haa shika ni akɛfeɔ lɛ baa shi waa, ni eji gbɛi ni atsɔɔ nɔ akɛ tsɔne lɛ tsaa nɔ ni he ehiaaa tsɔ lɛ ateŋ ekome.

Naagbai: Eyɛ mlɛo akɛ abaajie yɛ shikpɔŋhosomɔ kɛ jatsu ni tswaa lɛ shishi, ni nɔnyɛɛ ni yɔɔ tsɔne lɛ shishi lɛ haa etɔlɛ hewalɛ baa shi.

IV. Welding He Nibii ni Akɛtsaa

Nɔ ni anyɛɔ akɛ he fɔ̃ɔ nɔ fe fɛɛ ni hiɔ shi daa.

-Type: Butt welding: Hewalɛ ni nɔ kwɔ, nu ni tsiɔ ehe kɛjɛɔ he, ni sa kɛha nitsumɔ shihilɛi ni mli wa.

-Plug-in welding tsakpaa: Eyɛ mlɛo akɛ akɛbaawo mli, ehi kɛha paipii bibii-diamita. Sɛɛnamɔi: Ekɛ nu ko hoɔ, enyɛŋ ekpokpo.

Nɔ ni ehiii: 5. Ewa akɛ ajieɔ kɛjɛɔ mli. Nɔ krokomɛi ni akɛtsaa he: Klampiŋ nɔ ni akɛtsaa: Akɛtsuɔ nii yɛ hetsemɔ nitsumɔhei koni akɛtsu nii mlɛo. Sleeve tsakpaai: Akɛtsuɔ nii yɛ nibii ni akɛtsuɔ nii kɛ hydraulic gbɛjianɔtoi amli.

Halamɔ otii:

1. Halamɔ gbɛ ni atsɔɔ nɔ atsuɔ he nii yɛ nɔnyɛɛ kɛ hulutsoo naa: esa akɛ nɔnyɛɛ ni nɔ kwɔ kɛ hulutsoo ni nɔ kwɔ afee welded loo ring connection.

2. Kɛ damɔ tsɔne lɛ sui lɛ anɔ: Kɛha tsɔne ni yɔɔ oshara lɛ, atsɔɔ akɛ afee welding loo tenon-joint surfaces.

3. Susumɔ tsɔne ni akɛwoɔ mli kɛ ekwɛmɔ he: Flange ni akɛwoɔ mli lɛ mligbalamɔ shii abɔ.

4. Jara kɛ He: Wafer lɛ he ehiaaa ni eyɛ mlɛo.

V. Naagbee :

Kaa ni sa ji nɔ titri ni haa paipii lɛ feɔ shweshweeshwe kɛ nitsumɔ. Na gbɛtsɔɔmɔ ni he esa kɛ akaŋshii wiemɔi yɛ wɔŋmei valve, shinaa lɛ naa valve, kɛkwɛmɔ valvɛi lɛ. Moko ni oleTWSkoni ona tsabaa ni hi jogbaŋŋ kɛha ohehiamɔ nii.

Be ni akɛbaatsu nii: Alemle-25-2025