1. Gbɛjianɔtoo mlipɛimɔ

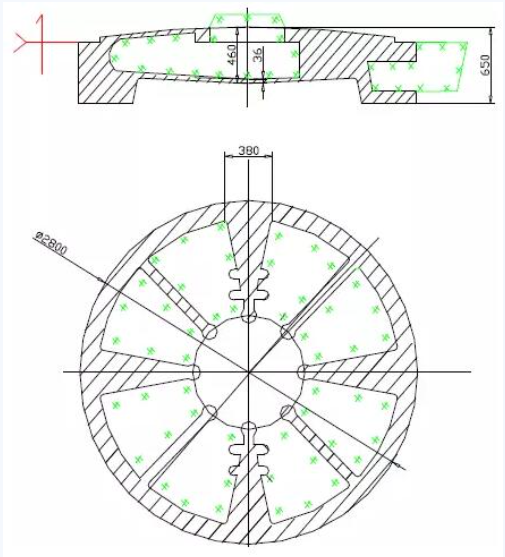

(1) Enɛŋmei valveeyɛ tsɔne ko ni tamɔ keeki ni yɔɔ kokroo, ni mligbɛ ŋmei lɛ 8 ni woɔ mɔ hewalɛ lɛ tsa ni efiɔ sɛɛ, ŋwɛi Φ620 bu lɛ kɛ mligbɛ ŋmei lɛ wieɔ, ni fãi ni eshwɛ lɛ .valvlɛ mli lɛ, ŋã lɛ mli ŋã lɛ mli saamɔ wa, ni eyɛ mlɛo akɛ ebaafite. Nibii ni ajieɔ kɛjɛɔ mli lɛ kɛ mligbɛ ŋmei lɛ mli saamɔ fɛɛ kɛ naagbai wuji baa, taakɛ atsɔɔ yɛ mfoniri 1 lɛ mli lɛ.

Nibii ni akɛwoɔ mli lɛ gbogbo lɛ mli ŋmɔlɔ lɛ srɔtoi waa, gbogbo lɛ ŋmɔlɔ ni fe fɛɛ lɛ shɛɔ 380mm, ni gbogbo lɛ ŋmɔlɔ ni baa shi fe fɛɛ lɛ ji 36mm pɛ. Kɛji akɛ tsɔne ni akɛwoɔ mli lɛ mli wa lɛ, srɔtofeemɔ ni yɔɔ hulutsoo be lɛ mli lɛ da, ni shwiemɔ ni ejaaa lɛ baanyɛ aha shwiemɔ ŋmeii kɛ shwiemɔ porosity defects aba mlɛo, ni no baaha nu atsɔ mli yɛ hydraulic kaa lɛ mli.

2. Gbɛjianɔtoo he ŋaa:

(1) Atsɔɔ he ni fãa lɛ mli yɛ Mfoniri 1. Okɛ naagbee ni bu yɔɔ mli lɛ awo adeka ni yɔɔ ŋwɛi lɛ nɔ, ni ofee ŋã muu fɛɛ yɛ teŋgbɛ ŋã lɛ mli, ni okɛ ŋã lɛ yitso lɛ atsake bɔ ni sa koni ŋã lɛ mli ŋã lɛ ni akɛfiɔ he kɛ ŋã lɛ mli nyiɛmɔ lɛ aya hiɛ kɛ́ atsɔ adeka lɛ nɔ. Stable, cantilever core yitso ni yɔɔ shwilafoi enyɔ ni yɔɔ afã lɛ mli lɛ kɛlɛ fe bu lɛ sɛɛ, bɔni afee ni ŋã lɛ mli hewalɛ ni tsiɔ nii kɛbaa shikpɔŋ muu lɛ fɛɛ mli lɛ teŋgbɛ lɛ afee nɔ ni tsɔɔ core yitso lɛ sɛɛ koni ŋã lɛ mli lɛ ahi shi shiŋŋ ni ehi shi shiŋŋ.

1:1.5:1.3, sprue lɛ kɛ sũ ni mligbɛ ŋwɛi ŋta ni ji Φ120 tsuɔ nii, ni 200×100yfractort 40mmt bricks lɛ mli fãi enyɔ lɛ toɔ he. 150×150×40 foam ceramic filter ko ni akɛwoɔ foidalɔ lɛ shishi, ni akɛ sũ tsɔnei 12 ni yɔɔ mligbɛ diameter ni ji Φ30 tsuɔ nii kɛhaa mligbɛ foidalɔ lɛ koni ekɛ ehe abɔ he pɛpɛɛpɛ kɛya shishigbɛ ni akɛshwieɔ shi lɛ nɔ kɛtsɔ nu lɛ bolleut lɛ nɔ. shwiemɔ gbɛjianɔtoo, taakɛ atsɔɔ yɛ Mfoniri 2 Essence lɛ mli lɛ

(3) Okɛ 14 ∮20 ŋwɛi kɔɔyɔɔ bu lɛ awo ŋwɛi ŋtayaa lɛ mli, okɛ Φ200 ŋã ŋã ŋtayaa ŋtayaa lɛ awo ŋtayaa yitso lɛ teŋgbɛ, okɛ dade ni mli ejɔ awo fãi ni mli wa kɛ wuji lɛ amli koni ona nɔmimaa akɛ ŋã lɛ mli walɛ ni sa, ni okɛ graphitization expansion fee yidser lɛ atsu nii koni ekɛ shishitoo mla lɛ atsu nii. Ŋã adeka lɛ dalɛ ji 3600×3600×1000/600mm, ni akɛ dade plɛte ni tsiimɔ ji 25mm ebɔ he koni ekwɛ akɛ eyɛ hewalɛ ni fa bɔ ni sa kɛ shifimɔ, taakɛ atsɔɔ yɛ mfoniri 3 lɛ mli lɛ.

3. Nifeemɔ nɔkwɛmɔ

(1) Nɔkwɛmɔnɔ: Dani obaafee nɔkwɛmɔnɔ lɛ, okɛ Φ50×50mm nɔkwɛmɔnɔ ni ji ŋmɛnɛŋmɛnɛ beaŋ nɔ lɛ aka bɔ ni ŋã ni mli ejɔ lɛ mli wa ha lɛ ≥ 3.5MPa, ni okɛ dade ni mli ejɔ lɛ kɛ foidalɔ lɛ atswa shi jogbaŋŋ koni ona nɔmimaa akɛ ŋã lɛ mli ŋã lɛ yɛ hewalɛ ni fa bɔ ni sa ni baanyɛ ajie graphite ni ajieɔ lɛ kpo lɛ naa beni expfitenes molten molten the molten iron lɛ . kɛjɛ foidalɔ lɛ fã lɛ nɔ ni eeetswa be kakadaŋŋ ni ekɛ ŋã ni shwieɔ shi lɛ aba.

Core feemɔ: Ajara ŋã lɛ mli awo fãi 8 ni yeɔ egbɔ mli kɛtsɔ ŋãi 8 ni woɔ mɔ hewalɛ nɔ, ni akɛtsaa ŋã lɛ mli kɛtsɔɔ teŋgbɛ ŋã lɛ mli. Nɔ kroko bɛ ni fiɔ sɛɛ kɛ tsɔne ni ajieɔ la kɛjɛɔ mli lɛ mli ja yitso ni yɔɔ teŋgbɛ lɛ. Kɛji akɛ anyɛɛɛ atsake ŋã lɛ mli ni Exhaust lɛ, ŋã lɛ mli shigbeemɔ kɛ kɔɔyɔɔ buji baaje kpo yɛ shwiemɔ sɛɛ. Akɛni ŋã lɛ mli he fɛɛ he lɛ da hewɔ lɛ, aja mli awo fãi kpaanyɔ mli. Esa akɛ ehiɛ hewalɛ kɛ shifimɔ ni fa bɔ ni sa koni ekɛkwɛ akɛ ŋã lɛ mli ŋã lɛ efiteee yɛ ŋmei ni ajie lɛ kpo lɛ sɛɛ, ni efiteee yɛ ŋmei ni ashwie lɛ sɛɛ. Deformation baa, koni ana nɔmimaa akɛ gbogbo lɛ mli ŋmɔlɔ ni yɔɔ tsɔne lɛ mli lɛ feɔ ekome. Yɛ yiŋtoo nɛɛ hewɔ lɛ, wɔfee ŋmei krɛdɛɛ ko, ni wɔkɛ kpãa ni haa kɔɔyɔɔ tsɔɔ mli lɛ fĩ ŋmei lɛ he koni wɔkɛgbala kɔɔyɔɔ ni jɛɔ ŋmei lɛ yitso lɛ mli lɛ mli koni wɔkwɛ akɛ ŋã ni akɛwoɔ ŋã lɛ mli lɛ mli ejɔ beni wɔfeɔ ŋmei lɛ. Taakɛ atsɔɔ yɛ mfoniri 4 lɛ mli lɛ.

(4) Adeka ni akɛkpaa naa: Akɛni asusu akɛ ewa akɛ abaatsumɔ ŋã ni yɔɔ ŋmei valve lɛ mligbɛ ŋã lɛ mli lɛ he hewɔ lɛ, akɛ ŋã lɛ mli fɛɛ ŋmei lɛ mli ŋmei lɛ mli ŋmei lɛ mli fãi enyɔ, akɛ zirconium ŋmei ni akɛ dãa fee lɛ shwieɔ klɛŋklɛŋ ŋmei lɛ nɔ (Baume degree 45-55), ni akɛ burne woɔ klɛŋklɛŋ ŋmei lɛ nɔ. Kɛ́ egbi lɛ, okɛ magnesium penti ni akɛ dãa fee lɛ (Baume degree 35-45) awo fã ni ji enyɔ lɛ nɔ koni nɔ ni akɛwo mli lɛ akakpɛtɛ ŋã he ni ekafee ŋmɔtɔ, ni anyɛɛɛ atsumɔ he. Akɛ yitso fã ni yɔɔ shishijee lɛ fĩɔ Φ200 dade paipi ni ji shishijee wu lɛ shishitoo mla titri lɛ nɔ kɛ M25 ŋtayaai etɛ, ni akɛ ŋwɛi ŋtayaa adeka ni ŋtayaai yɔɔ mli lɛ fĩɔ he ni akwɛɔ kɛji fã fɛɛ fã gbogbo lɛ mli ŋtayaa lɛ ji ekome.

4. Melting kɛ shwiemɔ gbɛjianɔtoo

(1) Okɛ Benxi ni yɔɔ shishigbɛ-P, S, Ti ni hi jogbaŋŋ Q14/16# tsina dade lɛ atsu nii, ni okɛfata he yɛ 40%~60% mlijaa mli; nibii ni he hiaa tamɔ P, S, Ti, Cr, Pb, kɛ ekrokomɛi lɛ akudɔɔ amɛ waa yɛ dade ni efite lɛ mli, ni aŋmɛɛɛ ŋmei kɛ fɔ gbɛ , nɔ ni akɛfataa he lɛ mlijaa ji 25%~40%; esa akɛ atsumɔ charge ni aku sɛɛ akɛba lɛ he kɛtsɔ shot blasting nɔ dani akɛtsu nii koni ana akɛ charge lɛ he tse.

(2) Nibii titrii ni akudɔɔ yɛ flɔnɔɔ sɛɛ: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (ni eshwɛ): 0.035% ~0.05%, shishi (residual) lɛ esa akɛ aŋɔ bɔ ni aaanyɛ.

(3) Spheroidization tsofa ni akɛwoɔ mɔ mli lɛ he tsofafeemɔ: akɛ magnesium ni baa shi kɛ shikpɔŋ nɔ sfɛroidization ni baa shi tsuɔ nii, ni nɔ ni akɛfataa he lɛ ji 1.0%~1.2%. Akɛ 0.15% ni ji tsofa ni akɛwoɔ mɔ mli shikome lɛ haa nodulizer ni yɔɔ paketi lɛ shishi lɛ nɔ, ni agbeɔ spheroidization lɛ naa. No sɛɛ lɛ, akɛ slag lɛ woɔ nitsumɔ mli kɛha 0.35% ni ji enyɔ lɛ, ni afeɔ 0.15% ni hoɔ yɛ be mli ni ashwieɔ lɛ.

(5) Akɛ hulutsoo ni baa shi oya ni akɛshwieɔ shi lɛ tsuɔ nii, ni hulutsoo be lɛ ji 1320°C~1340°C, ni shwiemɔ be lɛ ji 70~80s. Anyɛɛɛ afo dade ni mli edɔ lɛ mli yɛ be mli ni afɔseɔ lɛ, ni sprue kɔɔpoo lɛ eyi obɔ be fɛɛ be koni gas kɛ nibii ni fata he lɛ akabote ŋmɔtɔ lɛ mli kɛtsɔ foidalɔ lɛ nɔ. bu.

5. Casting kaa lɛ hetooi

(1) Kaa bɔ ni tsɔne ni akɛkaa nii lɛ mli wa ha lɛ okwɛ: 485MPa, sɛɛkuu: 15%, Brinell hewalɛ HB187.

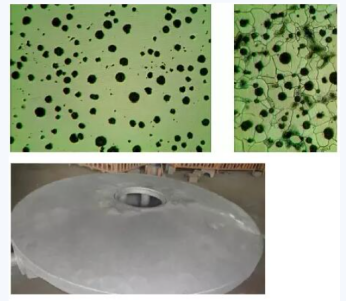

(2) Sfɛroidization lɛ falɛ ji 95%, graphite lɛ dalɛ ji grade 6, ni pearlite lɛ ji 35%. Atsɔɔ dade he gbɛjianɔtoo lɛ yɛ mfoniri 5 lɛ mli.

(3) Anaaa tɔmɔ ko ni aŋmala ashwie shi yɛ UT kɛ MT tɔmɔ ni ji enyɔ ni anaa yɛ fãi ni he hiaa lɛ amli.

(4) Ehiɛ su lɛ yɛ ŋmɔlɔŋmɔlɔ ni eyɛ ŋmɔlɔŋmɔlɔ (kwɛmɔ mfoniri 6 lɛ), ni nɔ ko bɛ ni akɛwoɔ mli tamɔ ŋã ni akɛwoɔ mli, slag ni akɛwoɔ mli, fɛ̃i ni akɛwoɔ mli, kɛ ekrokomɛi, gbogbo lɛ mli ŋmɔlɔ ji ekome, ni elɛɛmɔi lɛ kɛ nɔ ni mfonirii lɛ taoɔ lɛ kpãa gbee.

(6) 20kg/cm2 nu mli hewalɛ kaa yɛ nitsumɔ sɛɛ etsɔɔɔ nu ko ni hoɔ

6. Mumɔ naa

Taakɛ nɛkɛ ŋmei valve nɛɛ he gbɛjianɔtoo sui lɛ tsɔɔ lɛ, naagba ni ji ŋã wulu lɛ mli ŋã lɛ teŋgbɛ kɛ ŋã lɛ mli saamɔ ni wa lɛ he naagba lɛ naa tsabaa kɛtsɔ gbɛjianɔtoo ni ato he gbɛjianɔ lɛ nɔmimaa nɔ, ŋã lɛ mli ŋã lɛ feemɔ kɛ eshishitoo kɛ zirconium-based coatings ni akɛtsuɔ nii lɛ nɔ mi. Nibii ni akɛwoɔ kɔɔyɔɔ mli lɛ ahe gbɛjianɔtoo lɛ tsiɔ ŋmeii ni yɔɔ ŋmeii ni akɛwoɔ mli lɛ amli lɛ anaa. Kɛjɛ flɔnɔɔ mli charge kudɔmɔ kɛ foidamɔ gbɛjianɔtoo lɛ nɔ lɛ, akɛ foam ceramic filter screen kɛ ceramic ingate ŋaalee tsuɔ nii koni akɛkwɛ akɛ dade ni mli edɔ lɛ he tse. Yɛ tsofafeemɔi babaoo ni akɛwoɔ mɔ mli lɛ sɛɛ lɛ, dade ni akɛwoɔ tsɔne mli lɛ kɛ nibii srɔtoi ni akɛtsuɔ nii lɛ eshɛ nɔ ni mɛi ni heɔ nii lɛ taoɔ lɛ he .

KɛjɛTianjin Tanggu Nu-namɔ valv Co.,ltd. Kpɔlɔ valve, shinaa valv, Y-fɔmɔ nii, wafer plɛte enyɔ kwɛmɔ valvefeemɔ.

Be ni akɛbaatsu nii: Abɛibe-29-2023